High roller – A component journey

Aerospace bearings

Ball and roller bearings are essential to high-precision rotary components in aircraft, and need to deliver exceptional durability and consistent performance despite changes in temperature and air pressure. Materials used are customised based on the end application, including high temperature, stainless steels and more exotic alloys, such as Inconel.

After heat treatment, the masking is removed and the surface cleaned before inspection to ensure the part meets strict aerospace quality specifications.

After heat treatment, the masking is removed and the surface cleaned before inspection to ensure the part meets strict aerospace quality specifications.

For the perfect shape and smooth finish, bearings are put through final lapping and polishing processes.

End applications include landing gear, engine, control surfaces, and other parts or components.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote.

Denotes the parts of the component journey undertaken by Bodycote.

Inner strength – A component journey

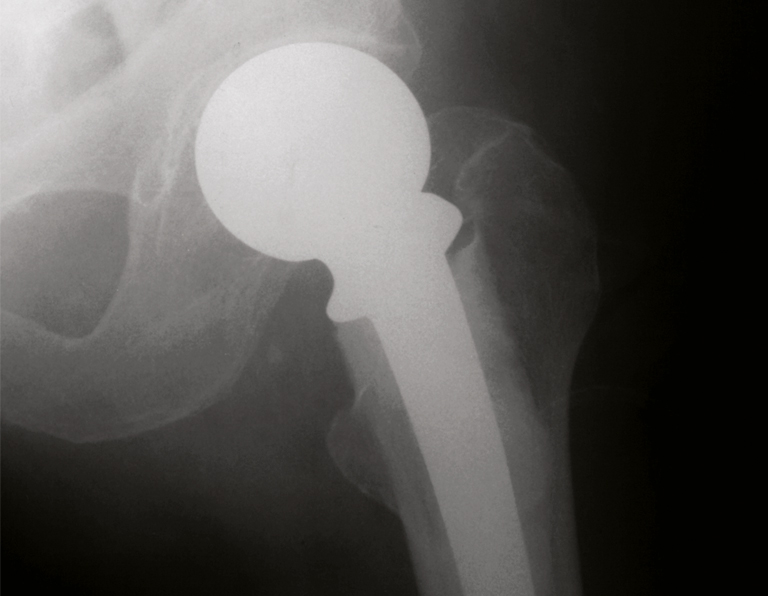

Medical implants

The stress on a hip or knee joint when a person jumps off a chair is equal to around 100 tonnes per square inch. Our bones, effectively composites, absorb such stresses regularly and effectively for much of our lifetime. When joints fail, they are often replaced with metal alloy implants. These implants must be incredibly strong, biocompatible, and able to last the lifetime of the patient. A combination of heat treatment, hot isostatic pressing and coating makes this possible.

Solution and ageing heat treatment is used to strengthen the implant.

Solution and ageing heat treatment is used to strengthen the implant.

End application – joint replacement.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote.

Denotes the parts of the component journey undertaken by Bodycote.

In gear - A component journey

Pinion gear

A pinion gear is a critical automotive component used in virtually all transmission units. During use, a vehicle places heavy demand on its transmission, requiring a fast and reliable response to the drive controls.

The gears require high strength and wear resistance in order to withstand the stresses applied to each gear during use. Bodycote's heat treatment processes, in particular Low Pressure Carburising (LPC), enable modern transmissions to deliver high performance and seamless response, even reducing noise during gear changes.

The gears begin life as low alloy steel.

The gears are machined to shape using a shaving or hobbing method.

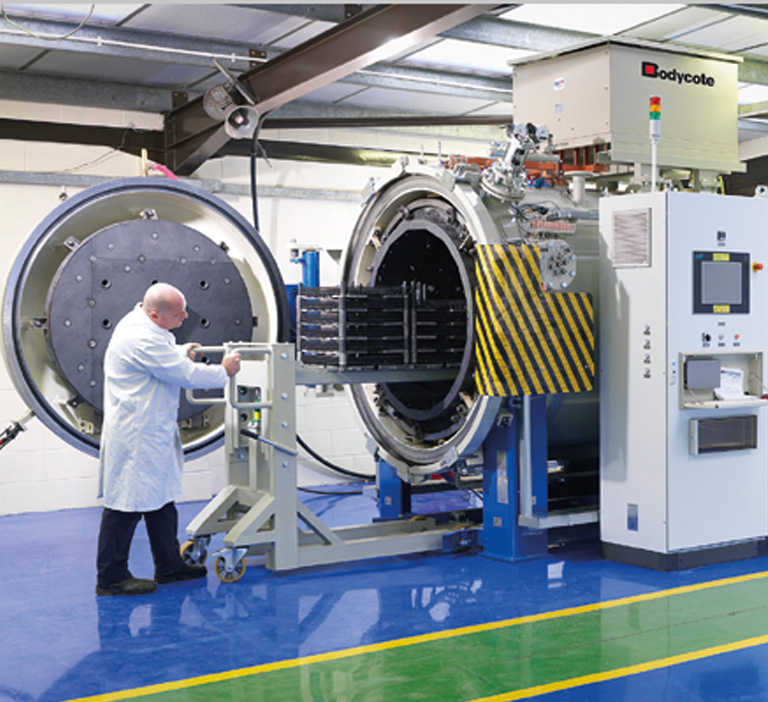

The gears are dimensionally measured before heat treatment to monitor and maintain repeatability of distortion. The gears are then heat treated using LPC to enhance functionality by adding a 'case depth' to provide strength and resistance to wear and tear.

The gears are dimensionally measured before heat treatment to monitor and maintain repeatability of distortion. The gears are then heat treated using LPC to enhance functionality by adding a 'case depth' to provide strength and resistance to wear and tear.

The gears are assembled into the transmission unit.

End application – automobile.

Bodycote component journeys

This is just one example of how Bodycote brings together the huge wealth of knowledge and expertise from across the Group to provide the vital engineering services our customers need.

For more component journeys visit www.bodycote.com

Denotes the parts of the component journey undertaken by Bodycote.

Denotes the parts of the component journey undertaken by Bodycote.